| |

The Liquiflo MAX® Series Gear Pumps will handle differential pressures up to 350 PSI and flows to approximately

20 GPM. Their unique, durable design assures extended life even in high-pressure pumping applications where other gear pumps could fail. The MAX® Series pumps feature Helical Gears in 17-4 PH Stainless Steel for smoother and quieter operation. |

| |

| Heavy-Duty Construction |

| The MAX® Series heavy duty shaft and bearing design make it last even when operating at high differential pressures for extended lengths of time. Its solid construction and oversized heavy duty bolts will minimize pump distortion caused by piping misalignment. The pump mounting bracket is made of corrosion-resistant 316 Stainless Steel or sturdy Cast Iron. |

| |

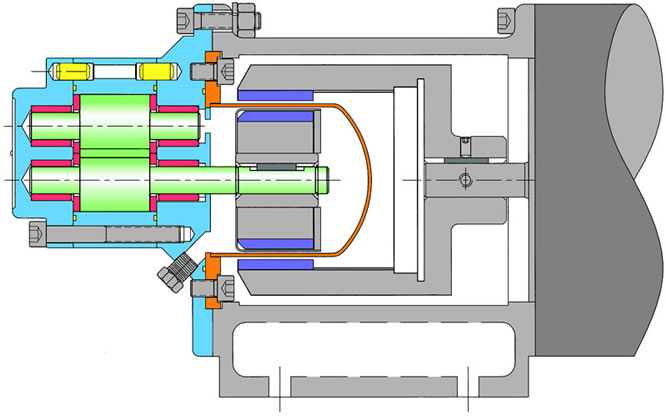

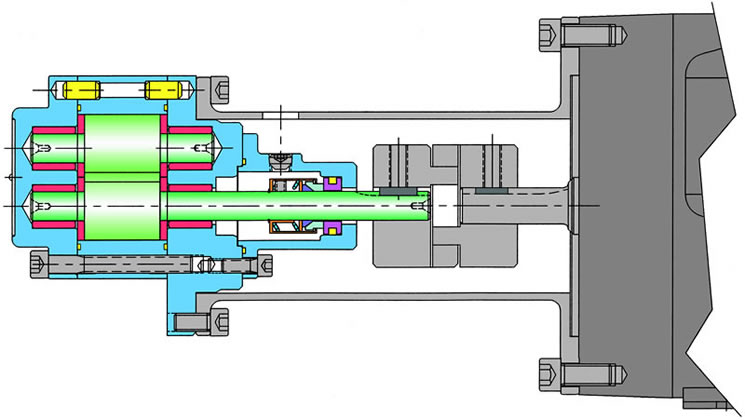

| Configuration |

| The MAX® Series pumps are available in either Single or Double Mechanical Seal or Mag-Drive configurations. The universal seal housing will accommodate either a single or double mechanical seal. The Close-Coupled design eliminates difficulties and inconveniences of manually aligning the pump and motor. MAX® Series pumps are offered in 316 Stainless Steel housings with a selection of internal component materials to optimize your selection for specific applications. |

| |

| |

|

|

| |

|

Models M0-M4 Sealed |

Models M0-M8 Mag-Drive

|

Close-Coupled |

& Models M5-M8 Sealed |

| |

Close-Coupled |

| |

| |

MAX-SERIES MODEL |

|

M0 |

M1 |

M2 |

M3 |

M4 |

M5 |

M6 |

|

M8 |

|

| |

Port Connections:

NPT/BSPT

ANSI 150# RF FLG* |

in

|

1/2 |

1/2 |

1/2 |

1/2 |

3/4 |

3/4 |

1 |

1¼ |

1½ |

| |

Max Flow Rate |

GPM |

0.4 |

1.0 |

2.4 |

3.4 |

5.1 |

8.6 |

11.8 |

15.0 |

19.3 |

| |

Max Differential

Pressure |

PSI |

350 |

350 |

350 |

350 |

350 |

350 |

350 |

350 |

350 |

| |

Max Discharge

Pressure** |

PSIG |

500 |

500 |

500 |

500 |

500 |

500 |

500 |

500 |

500 |

| |

Max Temperature |

°F |

500 |

500 |

500 |

500 |

500 |

500 |

500 |

500 |

500 |

| |

Min Temperature |

°F |

-40 |

-40 |

-40 |

-40 |

-40 |

-40 |

-40 |

-40 |

-40 |

| |

Max Speed |

RPM |

1750 |

1750 |

1750 |

1750 |

1750 |

1750 |

1750 |

1750 |

1750 |

| |

NPSHR @ Max Speed |

ft |

3 |

3 |

2 |

2 |

5 |

5 |

5 |

4 |

3 |

| |

Weight (without motor)

Sealed, Close-Coupled

Mag, Close-Coupled |

lbs |

32

38

|

32.5

38.5 |

33

39 |

33.5

39.5 |

34

40 |

42

42 |

54

54 |

55.5

55.5 |

56

56 |

| |

|

|

* ANSI 300# RF Flanges are optional.

** For flanged ports, pressure derating is required based on flange type and temperature.

NPSHR = Net Positive Suction Head Required |

| |

|

|

| |

| |

|

| |

|

Magnetically Coupled (sealless)

The magnetically coupled or mag-drive pump is the best method for handling toxic, noxious, crystallizing, or most other hazardous liquids since it completely contains the pumpage by isolating the drive shaft inside the pump housing. With no dynamic seal to leak or replace, the maintenance issues associated with seal leakage are eliminated. All Liquiflo gear pumps are available with magnetic drive. |

| |

|

|

Mechanical Seal

Mechanical seals are offered in single and double configurations and are used for chemical applications where leakage needs to be minimized or eliminated. The single internal mechanical seal is the most common seal type and is ideal for pumping clean liquids up to 5,000 cP viscosity. The double mechanical seal requires a flushing system and is typically used when pumping liquids that are viscous, abrasive, crystalize on contact with air or are very hazardous. Carbon vs. SiC seal faces are the primary choice for most applications up to 500 °F. SiC vs. SiC seal faces have high abrasion resistance and can be applied up to 500 °F. |

|

| |

| |

|

|

|